A long time before many people acquired our start in these kinds of industry, Building Management System Singapore (BMS or nowadays commonly known as BAS – Constructing Automation Systems) had been entirely swing. The truth is, you could go back as far as the late 1960’s to understand that some higher level of building manage persisted. The implementation may already are antiquated, but it got the position done given this available engineering. In the past what really commenced everything were pneumatic devices, actuators and valves controlling building HVAC equipment. It then migrated to add in PLC’s controlling other issues with a building, that are still greatly with play today. A number of you from the industry may contemplate PLC as Strength Line Provider ala X10. PLC available industrial and building automation world indicates Programmable Logic Controllers. In essence it’s stacks connected with I/O’s seeking talk about changes to put into action several sequence operations or events. A lot more ahead on this…

What is during this post is usually a shot on my part to further improve the awareness higher level of the almost untapped chance for AV control method integrators to migrate their footprint inside the BMS/BAS world. But before I give you my take i want to point out that, by no means will i have any assumptions or feel on any level which cures do for industry can supplant this Johnson Controls and Siemens around the world. I haven�t lost my senses. Although my little ones might disagree! That will put it in view the building manage industry generates a new comparable revenue within a 5 day function week we do in a entire calendar calendar year. It is exponentially larger compared to our industry’s blend revenue can actually approach hitting. Johnson Controls (JCI) and Siemens by itself generated 142 million in revenue not long ago. I just want to make the period clear. But with that said will, given that which you do in standard, there’s no question we need to be in on that revenue bash. What we bring towards table absolutely features significant perceptible worth. It’s time for those to garner the fair (or unfair) mention and here’s how…

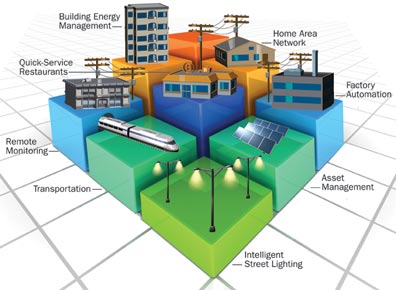

Allow me to begin by directing out how that lies. It’s definitely pretty cut and dry, we complete room manage, they (they being Siemens and even JCI) do building control. Sure, we can accomplish building and even campus wide manage and energy management singapore but it are invariably at the place level. They implement building control but rarely if ever take into consideration what takes put in place the tenant spaces for the room level. Most often renter spaces are occupied post CoO (certificate linked with Ownership). So the architect along with the GC are not always concerned with what goes on beyond the structure provided at time period of build-out. In such a illustration below, to the left is what a BAS manages, to the correct is cures target, in the middle is the spot that the opportunity lies.

Building-Management-Systems

As a way you're able notice, it’s in the center section the spot that the AMX RMS Source Management Collection www. amx. com comes towards play. This powerful operations technology is what aggregates each one of the room level use metrics, consumption data and device level demand responses with taken place inside the center. RMS then packages up your computer data into a language which the BMS/BAS system may understand and take in as necessary. Sounds simple, right? Once we all understand, there is nothing ever easy. Although it’s not concerning being simple, it’s about being worth an item. Globally we’re dealing with a business that's pushing a 50 % a trillion dollars. Just ponder this to have a minute, if we captured only one half of 1% of we would increase our sector profits by 3. 5B dollars!! When you check out the sheer dimension and magnitude on this opportunity, those of you which has been up for challenge can be met with little to never any competition. I call that “blue ocean”, go where not only a soul else is actually and hunt an item down! And even various other players start listed, the vastness on the size will leave adequate room for co-existence.

At this point let’s become honest, there’s no shortage linked with challenges here. What I believe is during succeeding is definitely about who could most effectively sell around the worthiness proposition towards stakeholders that investing room level integration included in the overall BMS/BAS package is a must. And given this multiple layers in this particular mix, especially inside the new construction step, garnering the attention on the correct group is really a lot easier in concept. Getting in early is certain, that said, in lots of situations, this is actually where good old-fashioned tenacity, perseverance and tenacity comes into play to play. Over and preceding that, being prepared for the onslaught to create code and regulatory challenges can strike an all-time large. It will furthermore be critical that you play efficiently and effectively inside the BIM (Building Information Modeling) entire world. This means which the solutions your offer you, the designs and submittals you submit as well as your whole approach to how we management the project from learn to finish will have to be dialed pertaining to BIM. world extensive web. autodesk. com

To help define this possibility, here is a failure of how building integration is categorized in most cases:

Standard Building: Constructing systems work independently, energy data efficiency and usage monitoring not inside the design

LEED Accredited Building: Series connected with operations exist using making systems, but they are still separate and they're not tied for an occupancy calendar and there exists limited energy files use monitoring.

High-end “Integrated” Building: Building systems are stuck just using an occupancy date, there is specific sequence of operations considering actual occupancy, a thorough building management dashboard is actually place for strength use monitoring, handling and reporting.

High Effectiveness “Smart” Building: Includes everything having an “integrated” building, plus management applications and business techniques available are seamlessly integrated while using the BAS.

You’ll observe that even for the very best performance level of creating integration no place or renter levels control, management or monitoring will be the main equation. We now have never been more poised to create a stronger value proposition for this particular picture. This is a golden possibility to never only augment what BMS purposes accomplish, but we can now position ourselves getting the integral “final” piece which will streamlines technology implementations and building operations management to add in the entire building.

If any one you out there have had success on this segment, please give us your feedback and experience up to now. I would furthermore very considerably welcome any one’s opinion on this post and regardless of whether you agree when camping around the opportunity available. I count on hearing from an individual.

Adrian is an Energy Management expert at teale.asia

(Teale Asia 33b Pagoda Street, Phone: 8500 2470) a

leading Energy Efficiency company in Singapore. Follow

Teale Asia on Facebook , Twitter, & YouTube.

Teale Asia

33B Pagoda Street

Five Tips for Energy Monitoring Singapore

June 3, 015

To lessen energy costs, manufacturers and commercial businesses in Singapore must first understand that they can manage energy consumption only when they monitor and understand energy monitoring Singapore.

If you’re interested in minimizing energy costs, here are five tips that will assist you get started:

1. Get buy-in on the top.

It’s easy to switch to fluorescent lights or raise the temperature around the A/C, but real energy management could require support from the top. How do you sell energy monitoring on the highest levels of your group?

Think about your everyday workplace supplies—pens, paper, staplers, etc. Good office and purchasing managers keep track of these things and how much has used.

Reducing energy costs

In the event that you’re a manufacturer, do you indiscriminately commit to plastic, solder, aluminum, or one of the other raw materials needed regarding production? No—you seek out greatest pricing, avoid waste, and tie the price of raw materials to the person product.

Why isn’t energy accounted for just like? Right now, it’s not. Power bills typically go right to personnel in accounts payable, who don’t ask questions but basically cut checks. Even if managers take a look at a power bill, the payment shows no detail on any time or where energy was utilised.

Increasingly, utility companies are pricing energy in line with the time of day it is employed or penalizing customers who exceed a maximum threshold throughout the billing period. And energy costs overall are rising to meet up with rising demand.

Utility companies are also offering incentives to customers who agree to reduce usage under certain disorders. In fact, these new developments in rates and demand-response offer savvy companies significant approaches to improve their bottom line, by paying closer attention to strength usage and costs.

Some larger businesses are creating new positions in their particular companies with titles like "energy manager" and "vice president of sustainability. " Individuals in these positions view energy less a fixed cost, but as one that can be managed to the company’s gain.

Though the return on investment will be evident later, investing in understanding your efforts usage now is well rewarding.

2. Gather data first; next manage.

Once you’ve sold energy monitoring to your organization, it’s time to begin gathering data—detailed, real-time data that you can see and analyze.

The data must be in depth enough and timely enough that you can see the spike in consumption when an air-handling unit as well as compressor cycles on. And it should be visible to all the key people inside your organization who use energy, providing them with not only the information, nevertheless the motivation to reduce costs.

Almost all energy monitoring applications naturally change into energy management applications. All things considered, it’s only logical that when you finally understand your overall usage behaviour, which of the individual machines inside your facility are the heaviest shoppers, how your consumption fluctuates, and what forms of changes are needed, you will need to automate and control these circumstances to make your business more strength efficient.

But the key is always to first fully understand what’s going on. You wouldn’t adjust your manufacturing processes soon you had compiled data that provided you a compelling reason to do this. Your energy use is no different.

Only after you’ve aggregated and evaluated a amount of energy-related data should you begin investing in automation hardware and exercising new forms of control over your processes, devices, and systems.

3. Choose the proper hardware.

Monitoring energy usage in commercial buildings and producers is very different from monitoring energy at your residence. A "big picture" summary involving overall energy consumption is certainly an excellent start, but it won’t provide the details and granularity you have to identify which of your systems and machines are your most significant energy consumers, and which are costing you essentially the most to operate. Choose industrial-grade energy monitoring hardware that may monitor, gather, and distribute energy data instantly.

On the other hand, you almost certainly don’t need a large, difficult, expensive building management system (BMS) as well as energy management system (EMS). You could start with a simple appliance so long as it meets certain requirements regarding connectivity with electrical equipment and (for the future) control systems.

Your monitoring system should be capable of connect to numerous power-related equipment. This equipment involves utility meters and load solar panels, any manufacturing machines specific to your business, and common building management systems like lighting and HEATING AND COOLING chillers and compressors.

The data you get through these should provide sufficiently high levels of granularity to be able to generate detailed reports and observe changes in each asset’s person power draw.

The monitoring hardware also need to be web-capable (to enable monitoring and alarming above the internet) and easy to configure.

Power monitoring, though well worth the time and effort for the costs savings it results in, is rarely the primary job of a single individual. As a result, a lot of people looking to implement energy monitoring have little time for complicated installations or setting. Rather, they need more of "out-of-the-box" appliance, like one involving Opto 22's OptoEMU Sensors, that may allow them to understand their consumption quickly but not take them away from their particular primary tasks.

But keep at heart that monitoring very often results in energy management. While simple to setup and use, the monitoring hardware you ultimately choose should also be compatible along with control and automation systems. Once you’re ready to manage energy along with monitor it, the data on the monitoring system must be simply integrated with control systems.

4. Consider your software options.

Energy monitoring hardware is merely half the battle. You need a software tool to aggregate your data so you can easily see, analyze, and use.

You've two options for energy overseeing software: cloud-based or local.

Cloud-based software is provided being a service by an online business. Your energy monitoring hardware sends data directly to the company, and any authorized person inside your company can see it on the internet, from anywhere, using a computer or sometimes a cellular phone or other mobile device.

Pulse Energy's Dashboard permits you to see detailed energy usage files

Cloud-based applications can provide easy, graphical interfaces to your files. Some cloud-based applications are sophisticated tools that permit you to organize and present data in varied ways knowning that even help you analyze strength usage. Pulse Energy’s Pulse and eSight Energy’s eSight are cases.

Local software, in contrast, is installed yourself company server or individual pcs. If your data is really sensitive, you may prefer to hold it in-house.

Local energy-monitoring software are available online (for example, eSight has software acquire and install) or be designed as custom software by your own engineers or a system integrator.

Available software varies with respect to the hardware you choose, so make sure the software and hardware you intend to use work together.

5. Understand that monitoring is simply a way to an end.

If you’re overweight, counting calories and weekly weigh-ins provide the information you have to make changes in your diet that will assist you lose those extra pounds. Energy monitoring works the identical way.

Monitoring simply for the sake of monitoring is just not the goal. Ultimately your goal is to reduce the price of energy for your company. Energy monitoring gives you the information you have to associate operational conditions with strength consumption statistics, so decision makers inside your plant or facility can enact efficient energy management policies.

The bottom line is reduce energy costs—and detailed energy monitoring is the first step to get you there.

Adrian is an Energy Management expert at www.teale.asia

(Teale Asia 33b Pagoda Street, Phone: 8500 2470) a

leading Energy Efficiency company in Singapore.

Teale Asia

33B Pagoda Street

Phone: 85002470

Website: www.teale.asia